I advised them that you would normally stick weld the sockets and that if you were going to tig the socket that the apropriate filler metal would be er 308 or er 309.

Welding 316 stainless with 308 rod.

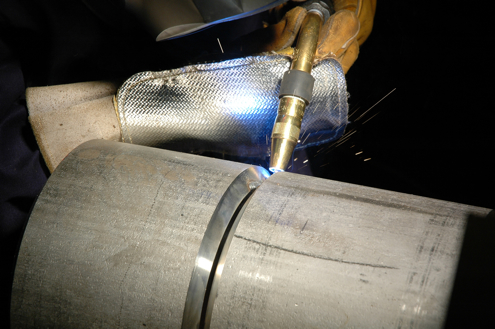

They were tig welding the sockets which is a little odd in it s self but they were also welding the 304l pipe with er 316l filler rod.

For tig gas tungsten arc welding gtaw process for 304 304l 308 308l 321 and 347 stainless steels.

In short 308l is usually used in welding stainless steel materials of grade 301 302 304 grades 316l for welding stainless steel base metals of grade aisi 316 and 316l 309l is used in welding mild steel or low alloy steel to stainless steel or for joining dissimilar grades of stainless steel together.

The major difference is 308 doesn t contain molybdenum.

The main application is for welding austenitic stainless steel with the same analysis as the weld metal aisi 304 and can also be used for welding aisi 301 302 308 and equivalent grades used for hospital apparatus pharmaceuticals equipment apparatus for nitric acid acetic acid milk soap fertilizer industries.

Stainless filler metal selector guide aisi type number 442 446 430f 430 fse 430 431 501 502 416 416 se 403 405 410 420 414 321 348 347 317 316l 316 314 310 310s 309 309s.

Elga s stainless steel welding rod family is called cromarod a quality range of electrodes that offer excellent weld bead shape and a self detaching slag.

It s highly recommended to use a 316l or 317l filler metal for welding 316.

Cg 12 is the cast equivalent of 309.

I d say the most common cause of weld corrosion of stainless is contamination before during or immediately after the weld process.

We have hand selected a range of elga s cromarod stainless steel welding rods which are supplied by the tin in 308 309 312 316 grades.

Cf 8m and cf 3m are the cast equivalents of 316 and 316l respectively.